Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

This injeciton molding machine can be used to make different type of plastic goods ,such as PET preforms ,PE caps ,PP bottles , caps ,PC ,PS ,ABS and so on

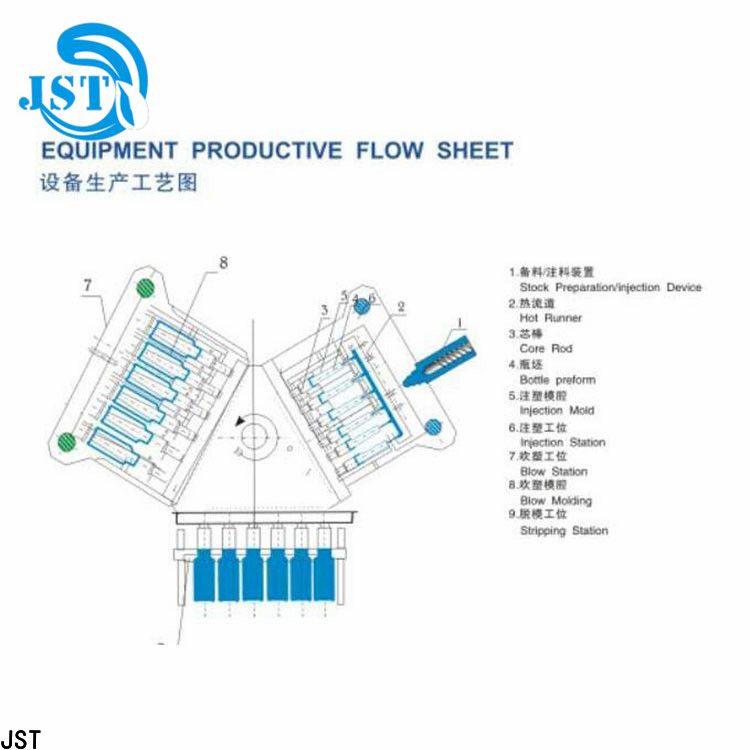

The following information ,it is for JST -45 Z injection blowing machine ,it can be used for PP,PE,PC material .

Usually the bottle size should be below 1000ml.

No | Name | Unit | Data | No. | Name | Unit | Data |

1 | screw stem diameter | mm | 45 | 17 | Stripping distance | mm | 120 |

2 | Length/diameter ratio of screw stem (L/D) | 20 | 18 | Mould size L ×W | mm | 480x390 | |

3 | Max. theoretical injection capacity | cm3 | 186 | 19 | Min. mould thickness | mm | 240 |

4 | Injection volume | g | 186 | 20 | Main motor power | kw | 22 |

5 | Max. injection pressure | MPa | 150 | 21 | Mould heating power | kw | |

6 | Max. theoretical injection speed ratio | cm3/sec. | 60 | 22 | Hydraulic system pressure | MPa | 14 |

7 | Max. distance of screw | mm | 165 | 23 | Lifting height of rotary table | mm | 60 |

8 | Twisting force of screw stem | N.m | 510 | 24 | displacement of compressed air | M3/min | >0.8 |

9 | Rotary speed of screw stem | rpm | 10-180 | 25 | Pressure of compressed air system | MPa | 1.0 |

10 | Plasticizing capacity | g/s | 13 | 26 | Cooling consuming volume | M3/h | 3 |

11 | Electric heating power of cylinder | kw | 6.5 | 27 | Overall size L× W× H | mm | 3100x1100x2200 |

12 | Electric heating control section | qty | 3 | 28 | Machine weight | T | 5 |

13 | Injection clamping moulding | kn | 280 | 29 | Product scale | L | 0.005-0.6 |

14 | Opening distance of injection mould | mm | 120 | 30 | Product height | mm | ≤200 |

15 | Blow moulding | kn | 30 | 31 | Product diameter | mm | ≤80 |

16 | Opening distance of blow moulding | mm | 120 | 32 | Central height of core bar | mm | 140 |

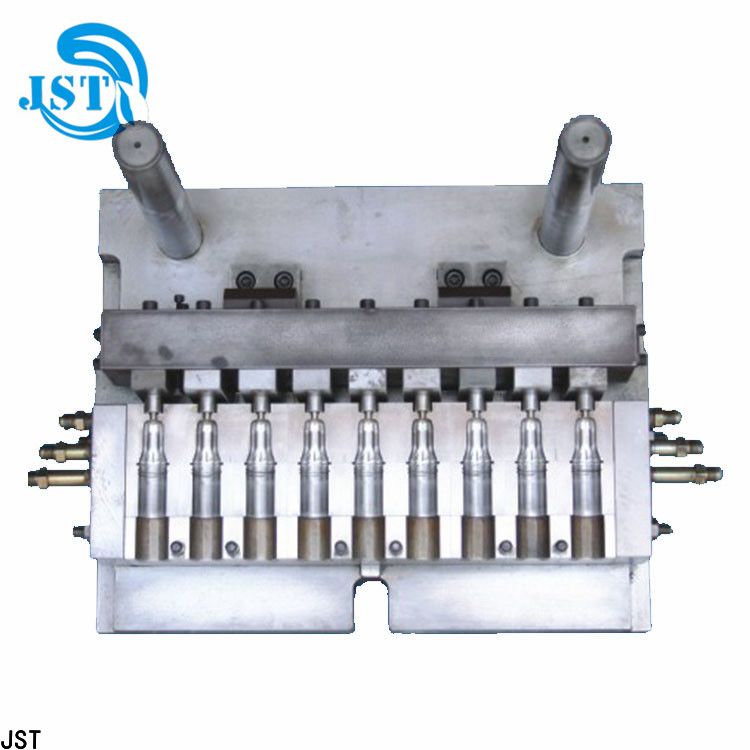

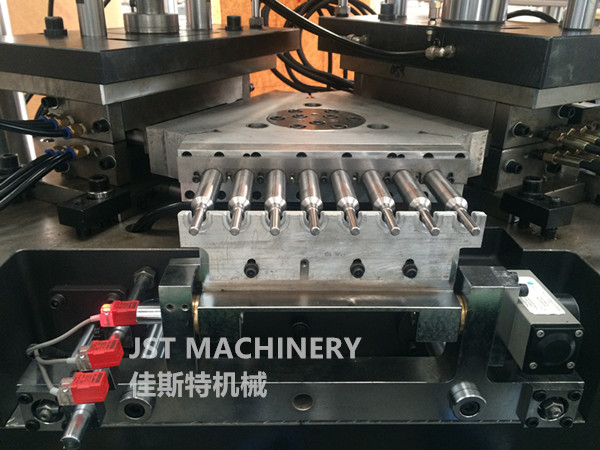

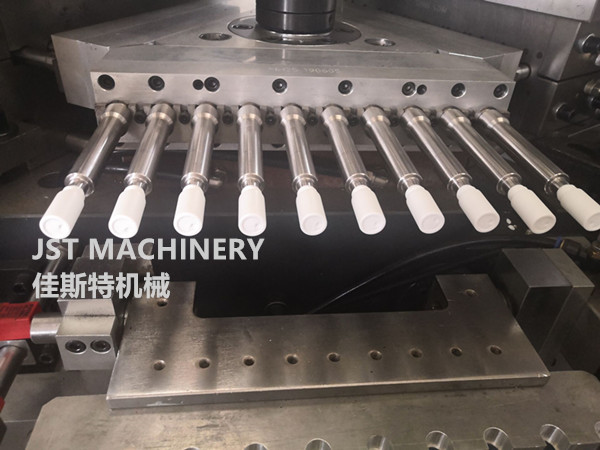

The necessary photo ,it is for spare parts :

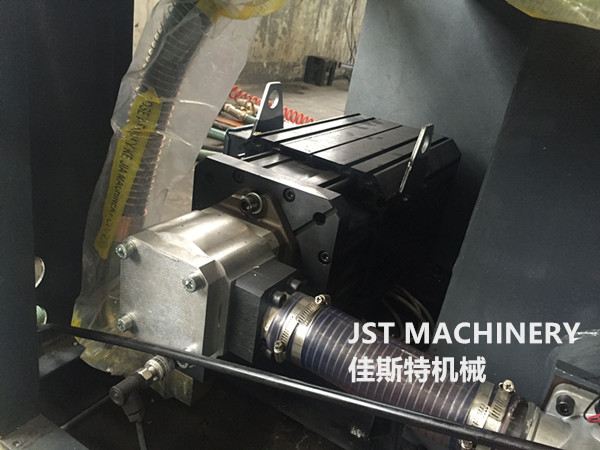

The following photos ,they are servo driver :

We will fix each corner of the machine in the container so that the machine will not move easily .

Sometimes client will come to discuss the detail.

And sometimes, client will come to inspect and learn to train the machines before delivery :

Usualy client will go to make the customs clearance ,and take the machines to their factory

Then our engineer will go to assemble them .

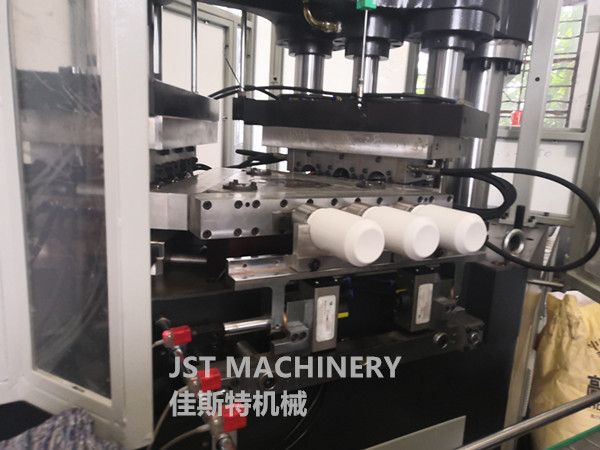

And then engineer will test each machine