Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

| Model | RCGF16-12-6 | RCGF18-18-6 | CGF24-24-8 | RCGF32-32-10 |

| Production Capacity (500ml) (b/h) | 3000 | 5000 | 8000 | 12000 |

| Filling Precision | ≤±5MM (Liquid Level) | ≤±5MM (Liquid Level) | ≤±5MM (Liquid Level) | ≤±5MM (Liquid Level) |

| Polyester Bottle Standard (mm) | (Bottle Diameter)50-92; (Height):150-310 | (Bottle Diameter)50-92; (Height):150-310 | (Bottle Diameter)50-92; (Height):150-310 | (Bottle Diameter)50-92; (Height):150-310 |

| Suitable Cap Shape | (Plastic Screw Cap) | (Plastic Screw Cap) | (Plastic Screw Cap) | (Plastic Screw Cap) |

| Water Pressure Of Washing Bottle (Mpa) | 0.18 | 0.18 | 0.18 | 0.18 |

| Gas Pressure (Mpa) | 0.3(Mpa) | 0.6(Mpa) | 0.6(Mpa) | 0.6(Mpa) |

| Gas consumption (m3/min) | / | 0.3 | 0.4 | 0.5 |

| Power | 3.5KW | 5.5KW | 7.5KW | 9.5KW |

| Weight | 2500 | 3000 | 3800 | 4500 |

| L*W*H (mm) | 2300×1650×2200 | 2600×1850×2200 | 3000×2150×2200 | 3500×2800×3150 |

By using mixing system, you can get room temperature filling or hot filling for juice.

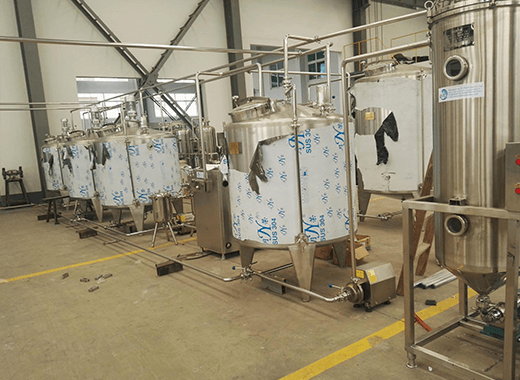

There are syrup melting tanks, mixing tanks, double filters, holding tanks, homogenizing machine, UHT sterilizer, juice storage tank, CIP cleaning system and steam boiler included.

We have fully automatic type or semi-automatic type. Usually for fully automatic type blowing machine, it can be connected to filling machine directly. The common type is JST-4A and JST-6A (It means 4000 bottles per hour and 6000 bottles per hour).

Read More

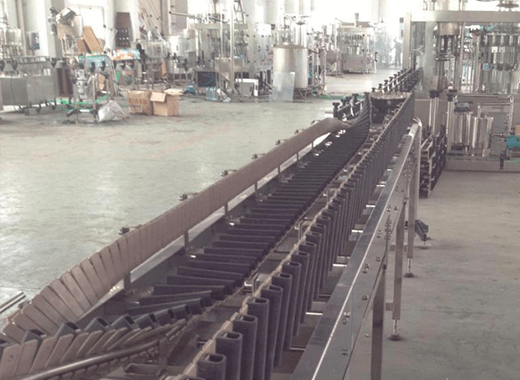

This type is for PET bottle rinsing filling and capping.

If you need glass bottle filling, the machine structure will be different. The price is also different.

It has cap cleaning device, juice vacuum system, flow back system, bottle neck spraying device, conveyor belt spraying device and waste water collecting tank.

The label is usually for juice and it is full body sleeve. And PVC sleeve shrink label is common.

Read More

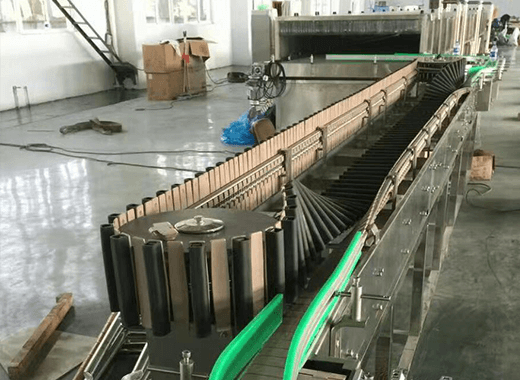

This is PE film shrink packing machine. This machine is economic. It can be connected to the filling machine directly by using conveyor belt.

There is high speed PE film shrink packing machine also (Linear type).

The PE film is also economic.