Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

This is full automatic type ,we have 3 cavity ,4 cavity and 6 cavity ,each type ,the blowing speed and machine price is also different

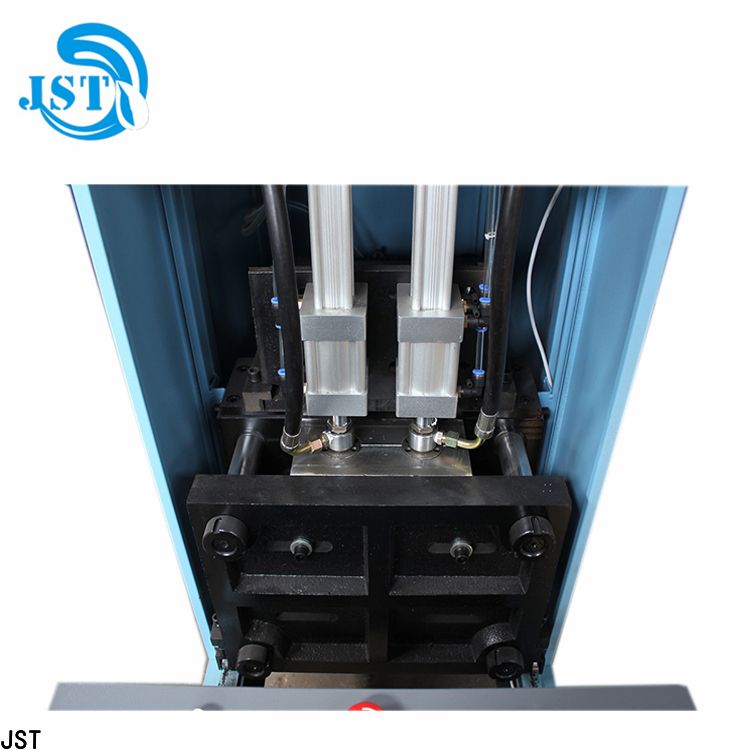

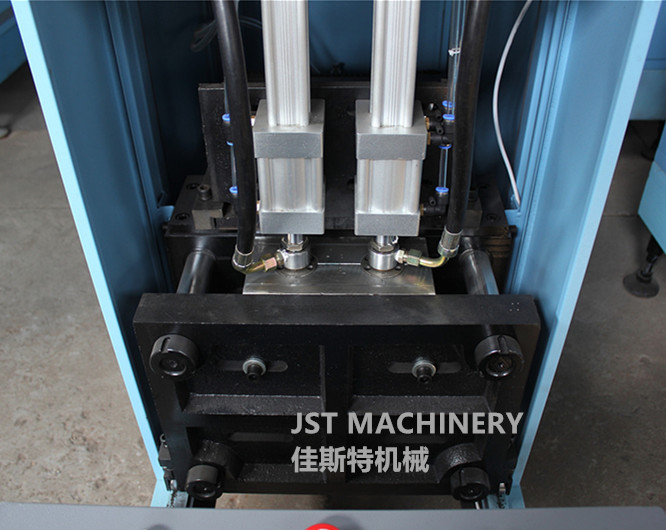

This is semi-automatic PET bottle blowing system ,usually it is made up of two blowers, one infrared oven , one high pressure air compressor ,one 3HP water chiller, one air cooling dryer ,two air filters and two sets of blowing molds .

Semi-automatic Stretch Blow Molding Machine | Productivity | 1500 Bottles per hour @ 500ml |

JST-1500 | Blowing capacity | 0.05L-2 liter |

Host size | 150X62X170 cm(There are two ) | |

Oven Size | 180X57X140 cm | |

Power | 15kw | |

package | Standard export wooden cases |

Air cooling dryer : can make the air more drier ,so that the bottle performance can be better .

Air filters : Can remove the impurity in the air .Make the bottles cleaner

water chiller, keep that the mold can be used for longer time .)

High pressure air compressor: it will provide the gas to the blower, help it work .and blow the PET preform into final bottles.

The mold: all the bottles will have the bottle drawing, And the mold is made according to the bottle drawing .and material is : 45# steel /

Usually we will pack the machines by using wrapping film.

Then we will pack them by using standard export wooden cases .

And at last ,we will load them into container

Sometimes client will come to discuss the detail.

And sometimes, client will come to inspect and learn to train the machines before delivery :

Usualy client will go to make the customs clearance ,and take the machines to their factory

Then our engineer will go to assemble them .

And then engineer will test each machine