Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

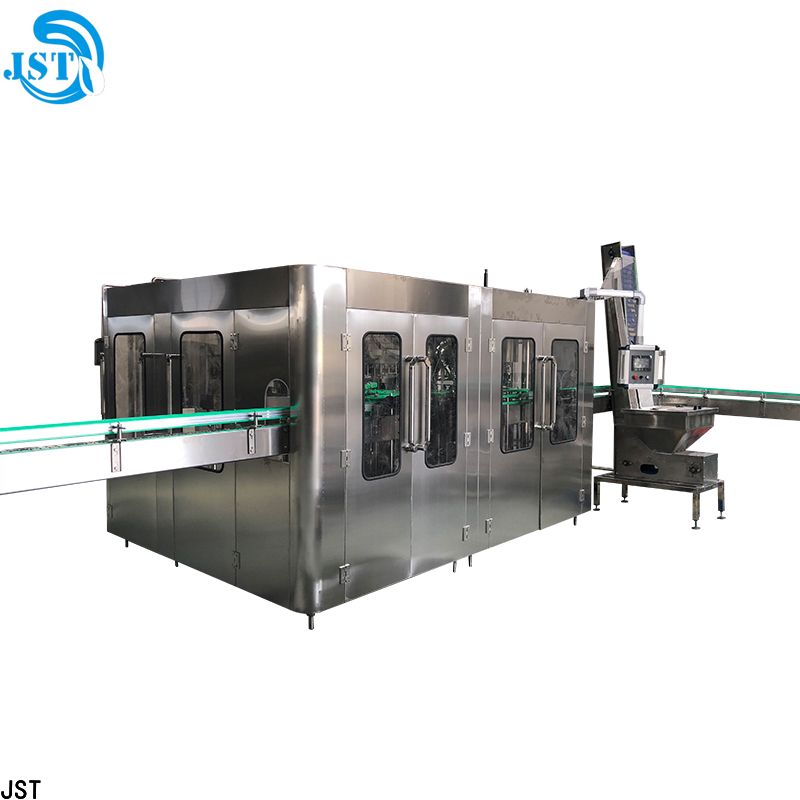

This filling machine ,it is used to fill carbonated drink into PET bottles .We have different type ,filling speed is also different ,such as linear type ,16-1-2-6,18-18-6 ,24-24-8 ,32-32-10,40-40-12 and so on .

Model:DCGF 32-32-10

Suitable bottle size : 250ml-2000ml.

Filling speed :0-12000 bottles per hour

Model | DCGF18-18-6 | DCGF24-24-8 | DCGF32-32-12 | DCGF40-40-12 | DCGF50-50-15 |

Head of washing, filling, sealing | 18-18-6 | 24-24-8 | 32-32-8 | 40-40-12 | 50-50-15 |

Production capacity (bottle/hour) | 0-4000 | 0-8000 | 0-12000 | 0-15000 | 0-20000 |

Suitable bottle diameter(mm) | φ=50-100 H=150-310 330-1500ml | φ=50-100 H=150-310 330-1500ml | φ=50-100 H=150-310 330-1500ml | φ=50-100 H=150-310 330-1500ml | φ=50-100 H=150-310 330-1500ml |

Filling pressure | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 |

Size (mm) | 2600*1800*2100 | 3000*2050*2250 | 3200*2150*2300 | 3500*2250*2350 | 4200*2250*2450 |

Weight(Kg) | 2500 | 3500 | 4500 | 5500 | 6500 |

1.This kind of complete set of gas drink filling machine combines washing,filling and rotary capping functions in one unit,is a fully automatic and high efficiency liquid packing equipment.

2.It is suitable for packing beverage containing gas drink . Its performance is as following all parts,for instance, filling valve, which directly contact medium are made of stainless steel or harmless material. So it conforms to the requirements of Food sanitation from JST company . Sealing parts are made of heat-proofing rubber, in order to meet the technique requirements of users to sterilization at high temperature.

3.Using programmable controller to realize fully automatic control from bottles entering to finishing packing, Using transducer as speed regulator, so the user can regulate the machine easily to suit different power requirements, Adopting equal pressure filling principle and current spring valves in order to assure beverage quality, Using advanced magnetic coupler to regulate cap-screwing torque, in order to assure capping quality.

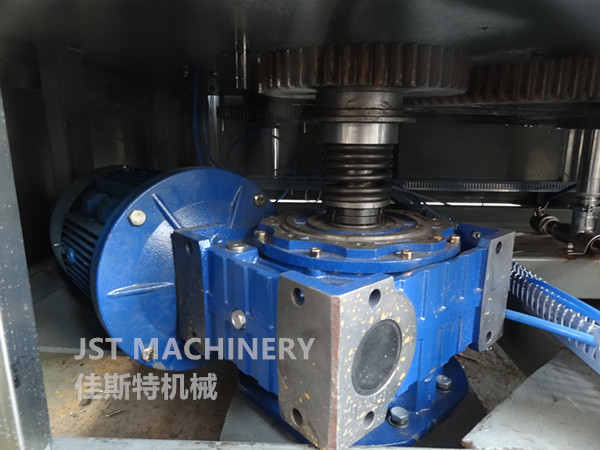

Please check the following detai photos:

Except the bottle rinsing filling capping machine ,you still need the water treatment system ,mixing tanks ,water chiller, beverage mixing machine ,bottle labeling machine ,date printing machine and bottle packing machine .

For water treatment system ,please check the following photo:

Beverage mixing tank and mixing machine :

Labeling machine photo :

PE film high speed shrink packing machine photo:

Usualy we will pack the machines by using PE wrapping film first

Then we will pack them by using standard export wooden cases

Sometimes,client will come to discuss the detail or inspect the machines before delivery

Usually clients need to finish the customs clearance ,and take the machines to their factory :

Then our engineer will go to assemble the machines for him

And at last ,engineer will begin to test each machine :