Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

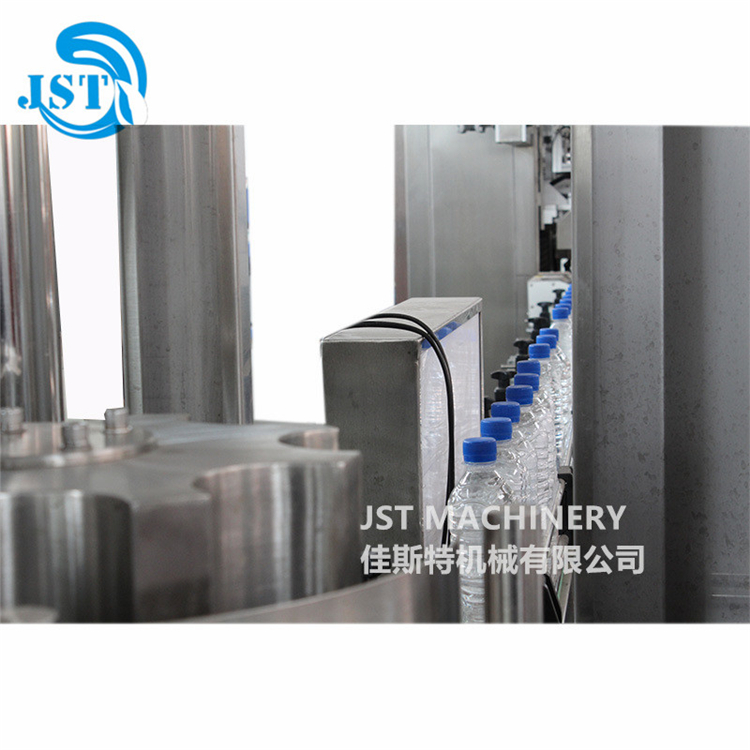

This is 8-8-3 rinsing filling capping machine for water . Filling speed for 500ml : maximum can be 2500 bottles per hour . Suitable bottle size ;200ml-2000ml

Bottle lowing machine → CGF 8-8-3 rinsing filling capping machine → PVC sleeve labeling machine → date printer →PE film shrink packing machine

Model | CGF8-8-3 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 |

Capacity(500ml)(b/h) | 0-2000 | 0-6000 | 0-10000 | 0-14000 |

Filling precision | ≤±5MM(Liquid Level) | ≤±5MM(Liquid Level) | ≤±5MM(Liquid Level) | ≤±5MM(Liquid Level) |

Water pressure | 0.18 | 0.18 | 0.18 | 0.18 |

Gas pressure | 0.6(Mpa) | 0.6 | 0.6 | 0.6 |

Weight | 2000 | 3000 | 4000 | 5000 |

Size (mm) | 2200×1600×1900 | 2800×1800×2200 | 3000×2180×2200 | 3600×2800×3150 |

The outset of rinsing can be adjusted by adjusting the angles of water distribution valve

All is made up of stainless steel 304 .

Under the machine ,there will be SS304 pipes to connect the waste water to water collecting tank.

Filling speed for 500ml : maximum can be 2500 bottles per hour .

Suitable bottle size ;200ml-2000ml

Power :3.75kw

If the liquid level in bottle is not proper, the position of filling must be adjusted by adding or decreasing the adjusting gasket to high or low the position respectively.

All the motor ,they are ABB type ,high quality ,even the motor on the air fan .

And under the machine ,the speed reducer and the motor ,they are combined ,without belt connect.

(ABB motor )

Touch screen photos:(Siemens )

Screw capping machine is most precision part in the 3-1 machine,it has a big influence to the goods stability and defective rate. our screw capping has following feature.

It has cap clelaning tunnel and cap elevator together.(The cap elevator ,it is lift sending type ,not air sending type )

Now our new design for three in one machine is like the followings :

First ,we will pack the machines with wraping film

And then we will pack machines with standard export wooden cases ,and load them into the container :

When machines arrive at client's factory ,our engineer will go to install the filling line for him .

First he will connect each machine one by one by using conveyor belt,then he will test each machine ,Please check the following photos :

Before placing order ,some clients will come to inspect our machines ,the following photos ,it is for our client :