Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

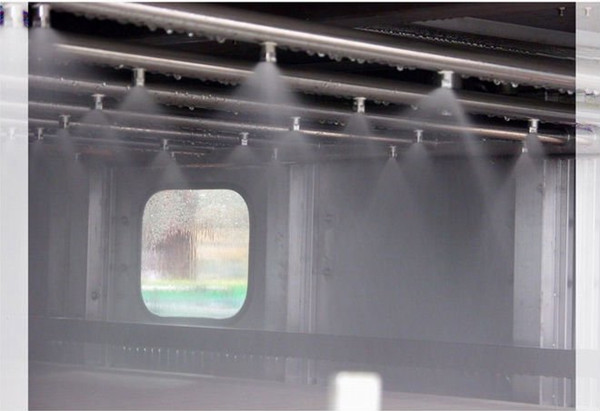

If for juice ,it is used to cool the hot filling into room temperature .If for beer ,usually it is used as Pasteurization tunnel

The equipment adopts three-stage or multi-stage treatment of circulating hot water spray sterilization, warm water precooling and cold water cooling. The sterilization and cooling time can be adjusted by frequency conversion according to the user's demand, and the automatic control is highly automatic. It can be used for atmospheric pressure pasteurization of all kinds of bottled, canned beverages, canned fruits and vegetables, etc. it can also be used for the cooling of tea drinks filled with PET bottles and the warm bottles of drinks containing gas.

We can make it to be 10 meters, 12 meters and so on .

The width can be 1.2 meters or 1.5 meters or 1.8 meters or 2 meters .

We will calculate the size according to your filling speed .

Product features:

1. High temperature resistant polypropylene (HTPP) chain plate and Japanese electrical components are used. The fuselage is made of stainless steel. The operation is stable and reliable, the overall structure is compact, and the appearance is sanitary and beautiful. ;

2. High quality plastic mesh belt chain plate, can work in high temperature for a long time (> 98), high temperature for a short time 104 ℃;

3. The solid cone wide angle nozzle has uniform and stable flow distribution and constant temperature field;

4. Comprehensive utilization of various energy and heat recovery technologies, energy saving and environmental protection;

5. The temperature sensor PT100 has a high measurement accuracy of ± 0.5 ℃;

6. Multi process combination, reasonable process, can handle a variety of materials;

7. The sterilization temperature is controlled by PLC touch screen.

8. The total processing time is controlled by frequency conversion, which can be adjusted according to the production process;

9. For PP bottles, plastic bags, roof cartons, glass bottles, tins and other products with non-circular packaging, automatic in and out mechanism shall be configured, and the connection with automatic conveying production line shall be smooth;

10. It can provide users with heating distribution testing service, and use expert system to monitor the temperature change in the whole process of production online.

11. Automatic control of sterilization temperature, stepless adjustment of sterilization time:

12. It can be widely used in sterilization and cooling of various bottled and canned acid juice drinks, electrolyte drinks, wines, condiments and other products;

13. The equipment can be designed according to the sterilization conditions and production requirements put forward by users

Working principle and mechanical structure:

(1) . working principle

The spray cooler is used to transport the sealed bottles into the spray area (spray set water temperature) through the circular plastic chain plate

Domain, to complete the cooling process, so that the bottle temperature to a certain temperature (set by the user), to achieve the purpose of cooling the bottle body.

The spray area is divided into three areas. The first area is provided by the first tank water in the water tank (the tank is divided into two tanks in total). The water temperature users can

If the temperature is higher than the set temperature, open the cooling pipe of the first tank water (the solenoid valve is opened), and then the

Water for cooling. The spray cooled water flows into the first tank of the water tank for recycling. Spray in the second area by circulating pump

Pump the second tank of water in the water tank into the cooling tower (a large water tank of more than 3m3 is provided by the user, and the water in the cooling tower flows into the cooling tower

Water tank) and then sent to the spray cooling pump through the cold water delivery pump (provided by the user) for spray cooling. The cooled water flows into the water tank

The second tank water in is sent to the cooling device by the circulating pump for cooling and recycling. Spray in the third area, provided by the user

Sterile water spray is used to dry the cooled bottles (cans) without water marks. Cooled water flows to the second in the tank

Trough. This machine adopts a water tank divided into two tanks. When the water level of the first tank is high, the water will flow into the second tank automatically, and vice versa. If the water level of the water tank is generally high, it will flow out of the overflow outlet pipe.

(2) , structure

The equipment is composed of body, transmission part, spray device and electrical control part.

1. The whole body is made of stainless steel according to the requirements, including manhole, regulating base, water tank, etc.

2. Conveyor

The device takes the motor with reducer as the driving source, and a ring-shaped plastic chain net conveyor belt is installed between the driving shaft at the bottle row side and the driven shaft at the bottle supply side, on which the product is transported.

(1) Structure

The device is composed of the following parts:

Plastic chain net;

A driving sprocket arranged on a driving shaft and a driven shaft;

Guide rail supporting products and chain net between two shafts;

Supporting roller of return chain net;

Transition plate between bottle feeding and bottle discharging conveyor belt and chain net;

A bottle guard rail installed on both sides of the conveyor belt to prevent the product from falling.

(2) Transmission chain network

The transmission chain net is used to transport bottles. The chain link and the long pin assembled with it are assembled. The chain link is not only used to transport bottles, but also used as the supporting point of the whole chain net.

(3) Bottle in and out structure: after the bottle is input from the bottle in belt, the bottle enters the machine body through the crossover plate. The transition plate is connected with the bottle in conveyor chain and the main drive chain network. The bottle out structure is the same as the bottle in structure.

(3) . spray device

The device sprays cooling water to the bottle (the spray water temperature can be adjusted), and the spray water from the nozzle is conical in normal condition. When the nozzle is blocked or the filter plate of the pump is blocked, the status is straight barrel. At this time, clean the nozzle and filter.

(4) . electrical control

1. The machine is equipped with electric control cabinet, various operation buttons and automatic temperature control system.

2. It is also equipped with a manual control system, which can be manually and automatically switched to each other for easy operation.

Sometimes client will come to discuss the detail.

And sometimes, client will come to inspect and learn to train the machines before delivery :

Usualy client will go to make the customs clearance ,and take the machines to their factory

Then our engineer will go to assemble them .

And then engineer will test each machine