Copyright © 2019 ZhangJiaGang JST Machinery Co.,Ltd.All rights reserved. Site Map Designed byiwonder.cn

Tel: +86-135 8442 1186

Email: admin@jstmachinery.com

This is our glass bottle beer filling machine ,the bottle inlet ,it is sent by flat conveyor belt .We have different type ,such as 8-8-3, 16-12-6, 18-18-6,24-24-8,32-32-10, 40-40-12 and so on.

Rinsing heads : 32Filling heads :32.Capping heads:10

Speed: 0-5000 bottles per hour for 500ml

Cap: crown cap or with ring together

Machine size : Length :3200mm,Width : 2800mm*Height :3150mm

Weight : 5000kgs .Working power : 9.75kw .

1, The rinsing machine using high-strength stainless steel bottles of spring-loaded folders, to ensure a stable reversal of the glass bottles. The nozzle is a plum-like structure can wash every corner of the sidewall and bottom to make the bottle clean.

But according to your requirement ,we will not make the rinsing system for you .

2, Filling machine from zhangjiagang jst machinery with spring-type mechanical lifting equipment to upgrade glass bottles, large bearing support floundering in the vat and use of guide-rod in the orientation of the structure, there are pre-cover features.

3, Using high-precision mechanical filling valve, with cylinder liquid level and the back pressure controlled by a variable signal proportional. Fast, stable, accurate, to be vacuum one at a time.

4, Stainless steel plunger and mechanical stirring gland-type magnetic reasonable cap to ensure that the gland is healthy and reliable. Hopper and the cap taking-cover, capping transmitted by magnetic. The capping is automatic unloading, reducing the rate of broken bottles.

5, Before the capping, use hot water bubble set to displace bottle neck air, ensuring the oxygen content of less than 0.15mg / L.

This type ,it is used to fill glass bottle .Before rinsing machine ,the bottles will be sent to the rinser by flat conveyor belt ,and inside the chain ,it is stainless steel 304 type .

Item | BGF14-12-4B

| BGF18-18-6B | BGF24-24-8B | BGF32-32-10B |

Capacity(500ml) (b/h) | 1000 | 2000 | 3000 | 5000 |

Polyester bottle standard(mm) | (Bottle Diameter)50-92;(Height):150-310

| |||

Suitable cap shape | (Plastic Screw Cap) | |||

Gas consumption(m3/min) | / | 0.3 | 0.4 | 0.5 |

Total power(kw) | 3.75 | 5.75 | 7.75 | 9.75 |

Total weight(kgs) | 2500 | 3000 | 4000 | 5000 |

Size (mm) | 2200×1700×2200 | 2450×1850×2200 | 2800×2180×2200 | 3200×2800×3150 |

Machine bottom detailed photo and Siemens touch screen photo:

Before filling ,you need the water treatment system and mixing system ,please check the following photos:

Bottle Pasteuurization tunnel photo:

Usually we will pack the machines by using wrapping film first :

Then we will pack them by using standard export wooden cases :

At last ,we will load them into container :

Usually client will go to their local airport to pick our engineer up

And then engineer will assemble the machines first

At last ,engineer will test each machine

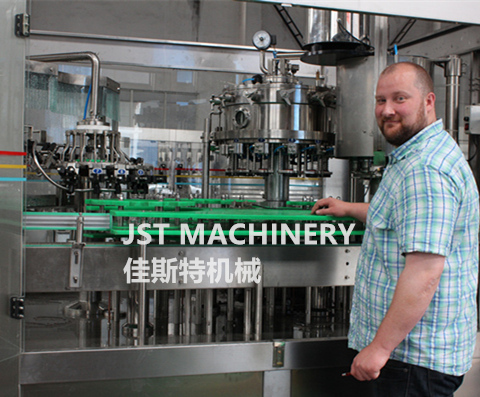

Sometimes, client will come to discuss the detail with us :